Smart Material Manufacturers Pivot to Solid-State Cooling

The new Zhar Research report, “Solid State Cooling Markets 2024-2044” finds that smart material researchers and manufacturers are pivoting to address cooling. Just as batteries and electricity generation transit from toxic, flammable liquids and gases to safe, “everlasting” smart solids, so is cooling technology beginning to do the same. That way lies the possibility of multi-mode - meaning cooling in several ways – and multipurpose composites. For example, just as some solar panels make both water and electricity, some smart cooling material makes water and cools and other smart materials double as a thermostat or make electricity while cooling. Most are load-bearing. Some are now transparent, so enjoy the space-saving and retrofitting opportunities resulting from that.

New operating principles

How does solid-state cooling work? Already the choice is considerable, embracing both active cooling (powered by electricity or other energy) and passive. For example, caloric cooling relies on entirely-solid ferroic phase change: it has negligible commercialisation as yet but great promise. Active cooling options now include thermoelectric, electrocaloric, magnetocaloric, barocaloric, elastocaloric, twistocaloric and – you guessed it – multicaloric options.

For a variety of given reasons, Zhar Research is underwhelmed by magnetocaloric and twistocaloric cooling. In contrast, it sees electrocaloric cooling as having enormous potential and barocaloric and elastocaloric as worth watching.

Thermoelectrics repositioned

Zhar Research is positive about good old thermoelectric because it is being reinvented with low-cost materials, ferrons, spin-driven effects and, this year, metal oxide framework thermoelectrics substantially funded for the first time.

The market moves towards thermoelectrics when powerful precise cooling in a small area is needed such as for the 1kW microprocessors arriving soon in robotics and elsewhere. There is work on low cost, wide area thermoelectrics but the winning calorics will probably get there first and exhibit four times the efficiency of thermoelectrics. Indeed, electrocaloric cooling may achieve four times the Coefficient of Performance (COP - the amount of heat removed per electrical energy consumed) that we get in today’s air conditioning.

Passive solid-state cooling

Zhar Research finds that the planned product launches and research pipeline for solid-state cooling will mainly involve passive cooling, typically fit-and-forget, affordable, without heat or toxicity issues. This includes new thermal interface materials, heat spreaders, heat sinks and other thermal conductors and – bursting on the scene - new principles of radiative cooling.

Materials in radically new forms

Solid-state cooling increasingly involves sophisticated forms of silicone, silica, boron nitride, aluminium oxide, titanium oxide, zinc oxide, lead zirconate titanate, and barium titanate. Favored polymers include epoxies, polyvinylidene difluoride and polyethylene compounds, an example being polyethylene containing nanoparticles of titanium oxide. Complexity is good news for suppliers seeking to avoid commoditisation. Appearing in the next-generation are such things as silica, cellulose and polyethylene aerogels, boron nitride and other particulates in nanocomposites and even multi-component particulates in a host polymer. Silicone is required as porous sponge or composite, for instance.

Diversity with thermal conduction

Thermal conduction may be electrically insulating or not and so new silicones, pyrolytic graphite, graphene, and various conductive polymers are introduced. The basic polymers mentioned earlier may form part of complex blends, copolymers and molecules. Some of those aerogels can thermally insulate while letting out infrared. They can be modified to usefully reflect as well. There is micro-patterning and micropyramids to create metamaterials and many chemistries and morphologies in advanced optronics in general for cooling, even giving the opposite of a greenhouse, still unpowered.

New physical principles

The variety is because a plethora of physical principles are brought to bear in a single paint, adhesive, film, coating, cladding or bulk material including conduction, convection, radiation, advanced photonics and that ferroic phase change within a solid. Other phase change materials such as vanadium dioxide enable self- switching according to humidity or temperature.

Watch PDRC

Of the more sophisticated multilayer options, Zhar Research is particularly impressed by Passive Daylight Radiative Cooling passively sending heat into space through the infrared window (8–13 μm). Indeed, practical versions do this and more. Limitations such as being on in winter and affected by weather are manageable. The tsunami of PDRC research involves coatings, thin films, metafabrics, aerogels and biodegradable surfaces. Aluminium phosphate, barium sulfate, calcium carbonate, silica, bismuth oxide, PTFE, silicon oxycarbonitride, zinc oxide and silicon carbide have been tried in various combinations, some with carbon or metal reflective layers. Complexes include polymethyl methacrylate PMMA film with a micropore array, silica-alumina nanofibrous aerogels, polyethylene mixed with nanoparticles of titanium oxide and silica nanoparticles. The jury is out on which combinations and formats will win but it will certainly be multi-mode in operation, at minimum controlling both thermal radiation and reflection.

Transparent

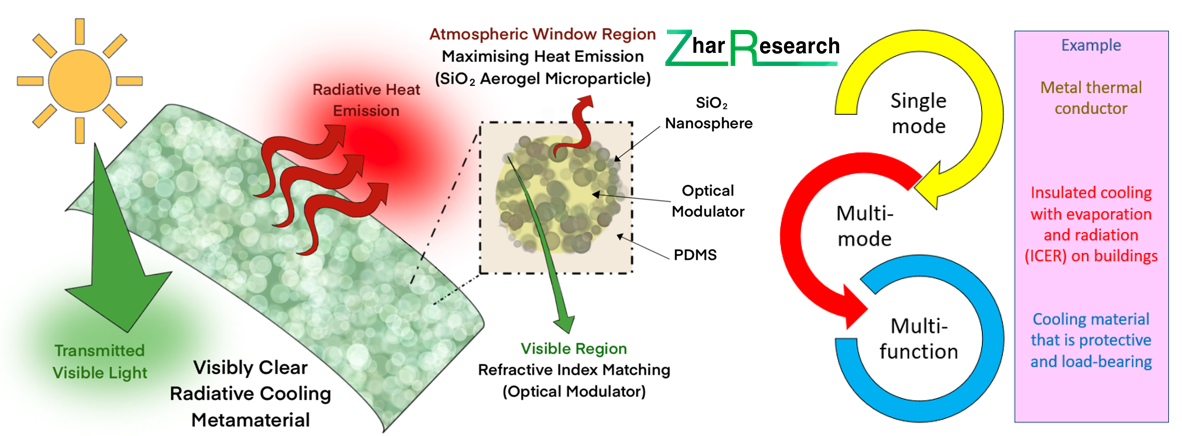

The many transparent versions of solid-state cooling will variously lead to invisible retrofit even on your glass high-rise, act as electronic drapes when needed and insulate as efficiently as any brickwork alongside. Solar cells may greatly benefit from such an overlayer. In one example, Advanced Functional Materials in 2022, 32, 28105822 reported visibly-clear radiative metamaterial for enhanced thermal management on solar cells and windows. An n-hexadecane optical modulator fills randomly distributed silica aerogel particles in PDMS silicone elastomer flexible laminate. This acts as both PDRC photonic cooler, potentially cooling by 5-12C, and suppression of visible light scattering. It has the potential to increase the output of solar cells by several percent and their life up to 50%.

Watch Janus and Anti-Stokes

The Janus emitter technology works from both sides and can be its own thermostat. Anti-Stokes fluorescence shifts frequencies to cool and commercialisation has just begun both for this and PDRC.

Advice

Dr Peter Harrop, CEO of Zhar Research advises,

“While it is good to be in at the beginning, added value materials suppliers should not expect to fully replace traditional vapor compression cooling for air conditioning any time soon. Indeed, the current regulatory and investment environment and architectural practices lead us to predict vapor compression dominating the value market even in 20 years from now. However, much new solid-state cooling can do part of the task in a given installation, reducing cost and stopping cities cooking by up to an extra 3C from aircon. The better options avoid toxicant issues. In contrast, today’s refrigerants mostly either damage the ozone layer, cause considerable global warming or have extremely serious toxicity issues.”

He adds,

“Substantial emerging applications such as new thermal interface materials for large batteries and cooling solar panels will still drive the market for solid-state cooling to more than triple to over $100 billion in 2024. Indeed, we shall raise that forecast if certain speculative options overcome their challenges. Patient companies with deep pockets will even target the total cooling equipment market which we project to reach $1.4 trillion in 2044, particularly driven by global warming and developing countries being in hotter places anyway as they become responsible for more of the value market. Those people will buy much more cooling equipment so it will become urgent to make it more affordable and retrofittable, taking space and greener in all respects.”

Press release distributed by Pressat on behalf of Zhar Research , on Friday 8 September, 2023. For more information subscribe and follow https://pressat.co.uk/

Smart Materials Solid State Cooling Manufacturers Batteries Electricity Passive Cooling Elastocaloric Thermoelectrics Microprocessors Polymer Computing & Telecoms Consumer Technology Environment & Nature Government Manufacturing, Engineering & Energy

Published By

anastasiams@zharresearch.com

https://www.zharresearch.com/

Dr Peter Harrop

peterharrop@zharresearch.com

Visit Newsroom

You just read:

Smart Material Manufacturers Pivot to Solid-State Cooling

News from this source: